Comments?

For the basics, see

- Website & Privacy Policies

- How To Get Involved

- The Role of the Park

Search options:

Department Site Map

Custodians:

About Cob

About Cob

On this page:

The Basics | Resources/Further Reading | Quick Figures/Benefits

About Cob

posted June 15, 2006

The Basics

What's Cob?

Clay, sand, and straw,

mixed with your feet.

Cob is a building material made by mixing clay, sand, and straw by foot, and forming it by hand into walls. The word "cob" is an Old English word and means "lump" or "loaf", and the lumps that the material is formed into before being integrated into the walls often do resemble loafs of bread.

This building method lends itself to curvy, sculptural shapes, and invites the participation of any and all who are interested in giving it a try. Cob buildings have been called "ecstatic", in that they seem alive to the people who enter them. They exist all over the world, especially in parts of Africa and the Middle East, but there are also hotspots of cob activity in Oregon, Wisconsin, California, Mexico, New Zealand, Wales, Vancouver, and now, Toronto.

Cob walls can last for a long time (there are buildings in the UK that have been continuously inhabited for 500 years). Because cob is suceptable to damage if it gets wet too often and for too long, there are two building features that usually accompany cob to help alleviate concerns about water. Generous roof overhangs protect the wall from getting too much direct rain, and a high foundation stemwall keeps the cob up off the ground and away from most flooding. Many people also plaster their walls to add extra protection and help prevent excessive moisture from being absorbed by the walls.

The foundation usually consists of some kind of stone work, either dry laid, or mortared together. Other foundation systems include rammed earth tire foundations and earth bag foundations. People often employ a rubble trench system for the underground portion of the foundation, which usually combines foundation and drainage functions.

The Mortar and Plaster

Cob walls need to breathe. It is essential that air and water be able to permeate both sides of the wall, and that moisture be able to work its way out without running into any barriers.

There have been reported failures of cob walls, usually restorations, that have been coated with a layer of Portland cement. The cement traps moisture in the wall and, instead of migrating in and out, the water gets trapped between the cement and the cob. Over time, it builds up, the cob becomes soaked, and the wall suddenly collapses.

There are at least two options for protecting a cob structure without resorting to Portland cement. Many people use a clay plaster, which is simply a refined version of cob. The other is called Roman Concrete.

There are many Roman concrete recipes, but the one that Cob in the Park is using consists of:

- One part soaked builder's lime (limestone that has been crushed, burnt, slaked, dried out and then soaked)

- two to three parts sand

- a small amount of Pozzolanic additive to help the lime set faster. The Romans added volcanic ash to speed up reaction time. A common additive these days is powdered burnt clay.

Roman concrete sets much more slowly than Portland cement, which means that we can spend a whole day leisurely mortaring stones together. It sets by slowly absorbing CO2 from the atmosphere, and may take as long as 100 years to fully cure. Roman concrete is self-healing in that small cracks can eventually heal over as the concrete cures, and it reportedly remains more flexible than Portland, increasing its ability to withstand shocks.

Whether mortaring the foundation or plastering the walls, the mix is the same, except that usually the plaster has some fibre like chopped up straw added to it.

For the basics

Download your own copy of the booklet

posted June 15, 2005

Resources

Cascadia Cob Slideshow (ON): cascadiacob

- extensive image gallery of benches, walls and buildings in the United States

City Farmer (BC): http://www.cityfarmer.org/cob.html

- Oven and garden shed in Vancouver

City Repair Oakland West (US): http://www.cityrepair.org/wiki.php

- small earthen outdoor theatre, currently in construction

Cob Cottage Company (US): http://www.cobcottage.com

- The people who started the cob revival, based in Oregon

Cobworks (BC): http://www.cobworks.com/

- images of their various projects in Canada and around the world

Down to Earth Building Bee (BC): http://www.alternatives.com/cob-building/

- small structure in downtown Vancouver

Earthed World (UK): http://www.earthedworld.co.uk

- extensive photo gallery of buildings, benches and ovens

Groundworks (US): http://www.cpros.com/~sequoia/lois.html

- story of a woman who is building her own home

OK OK OK Productions (US) http://www.okokok.org

- Earth Bag Bulding, with a number of interesting cases

Outta the Box (US): http://www.outtathebox.org

- photo gallery of the courtyard wall they built last summer in Madison, Wisconsin

Stanley Park Earthen Architecture Project (BC): http://www.stanleyparkcob.ca

- small structure in Stanley Park, Vancouver

California Institute of Earth Art and Architecture: http://www.calearth.org/

posted April 01, 2007

Quick Cob Figures - Benefits of Cob

Just how much, how many, and what go into (or don't go into) the making of the cob structures?? Here are a few interesting figures to give you an idea of some of the ways cob construction is environmentally and people friendly:

Cob Courtyard Wall

Volunteer Participation

Summer 2005: approx 500 volunteers

Materials diverted from landfill

Clay: 337.5 cubic feet

Concrete: 225 cubic feet

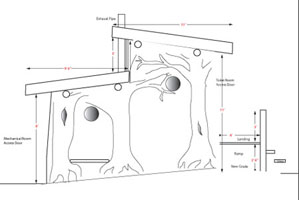

Bio-toilet/Earthen Building (cancelled in 2007)

Volunteer Participation

Summer 2006: approx 200 volunteers  Summer 2007: project on hold

Summer 2007: project on hold

Summer 2008: approx 500 volunteers

Projected total: 700 volunteers

Projected total: 600 volunteers

Materials to be diverted from landfill

Clay: 477 cubic feet

Estimated reduction in conventional toilet uses per season:

Approx 6,900

Estimated water use avoided

(based on 6 litre flush): 41,400 litres

(based on 13 litre flush): 89,700 litres

Average: 65,550 litres

The Phoenix toilet model is rated to take up to 100 uses per day in the summer months. An average season would probably see about 6,900 uses of the facility. Taking this many flushes out of the conventional waste system saves approximately 65,550 litres of potable water from being flushed down the toilet. It also reduces:

|

-Additional water use during the sewage cleansing process; |

-Emissions from creating the energy; |

Printer friendly version

Printer friendly version